Fault Within a Wind Farm Inter-Array Cable

Testing of the recovered cable identified a faulted 8-metre section of the cable and this was targeted for dissection by BPP-TECH at their workshop facilities. The dissection revealed two distinctly separate faults, very close together (approximately 30mm), ultimately caused failure of the core sheath.

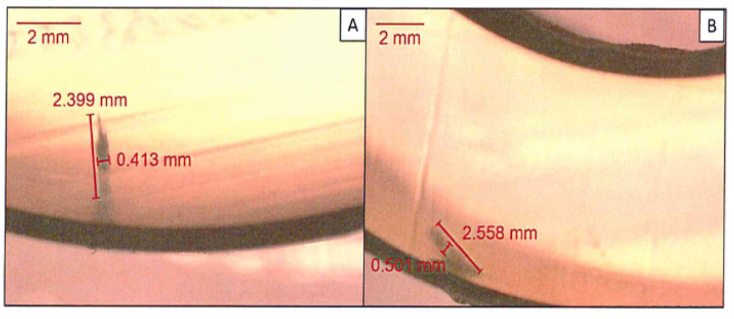

Microscopy of the insulation layer revealed two underlying features directly beneath burns to the outer semi-conducting layer, directly related to the cable failure and illustrated below.

Detailed microscopy showed that the main damage was caused mechanically. The presence of fibres entering the semiconducting layer and becoming entrapped was indicative of a piercing action from outside. Mechanical damage was visible to the copper screen wire directly above one of the XLPE insulation features. Holes in the aluminium foil displayed inward deflection with no evidence of burning or melting of the aluminium. A selection of BPP-TECH microscopy images illustrates typical evidence of mechanical damage.

The faults were situated in the outer zone of the cable diameter, which is the cable core’s most susceptible surface to direct mechanical damage.

During the piercing, a shield wire also sustained mechanical damage (as observed during microscopy) resulting in reduction of cross-sectional area causing it to break. Tape fibres were found entrapped in the outer semiconducting insulation screen as further evidence of entry and penetration. The unknown object or objects were retracted afterwards and remain unidentified.

Based on this evidence, it was concluded that the penetration happened post-manufacture, due to the combination of location of the faults, features of the faults, and the various testing and FAT documentation.